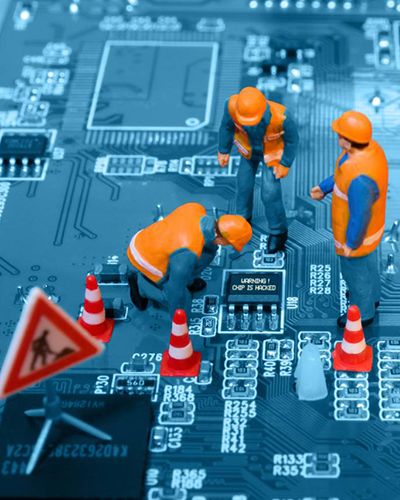

Hardware Engineering

We offer a wide range of services related to system engineering, including:

- Hardware Design and Development: Designing and developing custom hardware solutions to meet specific requirements and objectives. This involves schematic capture, PCB layout, and prototyping using industry-leading tools and technologies.

- FPGA and ASIC Design: Designing complex programmable logic devices (FPGAs) and application-specific integrated circuits (ASICs) for specialized applications. This includes RTL design, synthesis, place-and-route, and verification to achieve optimal performance and functionality.

- Compliance with DO-254: Ensuring compliance with DO-254 standards for the design assurance of airborne electronic hardware. This involves comprehensive planning, verification, and validation activities to achieve certification for safety-critical hardware.

- Electronic System Integration: Integrating hardware components and subsystems into larger electronic systems, ensuring compatibility, reliability, and performance. This includes hardware-software co-design, interface definition, and system-level testing and validation.

- Testing and Verification: Conducting thorough testing and verification activities to ensure the functionality, reliability, and safety of hardware designs. This includes functional testing, environmental testing, and compliance testing to meet industry standards and regulatory requirements.

- Reliability Engineering: Incorporating reliability engineering principles to identify and mitigate potential failure modes and improve the lifespan of hardware components and systems. This includes reliability prediction, testing, and analysis to ensure robustness and durability.

- Certification Support: Providing support for certification processes and compliance with industry standards and regulations. This includes documentation, traceability, and evidence generation to demonstrate compliance with applicable requirements.

- Prototyping and Manufacturing Support: Assisting with prototyping and manufacturing processes, including design for manufacturability (DFM) and design for testability (DFT) considerations. This ensures smooth transition from prototype to production and efficient manufacturing processes.